Conversion costs can help identify inefficiencies by highlighting excessive labor hours or disproportionately high overhead expenses relative to output. Analyzing trends in these costs may reveal issues such as low worker productivity, equipment downtime, or wasteful processes. Monitoring and comparing conversion costs across periods or production lines supports better decision-making and operational improvements. Thus, conversion costs are all manufacturing costs except for the cost of raw materials. It is retained earnings the direct labor plus any manufacturing overheads needed to convert raw materials into a finished product. Direct labor, as mentioned above, refers to the salaries of production workers.

How to Hire a White Label PPC

By calculating the conversion cost per unit or per output measure, managers can compare the performance and productivity of different production units, departments, or divisions. Managers can then use this information to allocate resources, set goals, reward or motivate the workers, or make outsourcing or insourcing decisions. From a managerial perspective, understanding the conversion cost ratio allows businesses to evaluate the allocation of resources and identify areas for improvement.

Colorado Springs SEO

In such cases, it is time-saving to calculate equivalent units and unit costs by combining direct labor and manufacturing overheads instead of doing separate calculations for the two cost items. Direct labor costs are a critical component of conversion costs, representing the wages and benefits Budgeting for Nonprofits paid to workers directly engaged in the production process. These individuals contribute their time, skills, and effort directly to the manufacturing of goods. Examples of direct labor include assembly line workers, machine operators, and technicians. Calculating direct labor costs involves multiplying the total hours worked by the applicable wage rate, including any additional benefits or allowances. The key difference between prime and conversion costs is the calculation of both the costs.

International Keyword Research

- PPC Intelligence In the fast-paced world of digital marketing, staying ahead of the competition is crucial.

- It is the direct labor plus any manufacturing overheads needed to convert raw materials into a finished product.

- Subsequently, all other expenses are subtracted from the gross profit to calculate the net profit of the business.

- It excludes the salary of management, office staff, and other people who are not working directly with the products.

- By understanding and effectively managing these costs, businesses can enhance their competitiveness, improve profitability, and make informed decisions regarding production processes.

- How to Download Youtube Videos without Premium Are you tired of buffering videos or struggling with inconsistent internet connections while trying to enjoy your favorite YouTube content?

By understanding the nuances of conversion costs, businesses can enhance their financial performance and achieve sustainable growth. Remember, the key lies not only in calculating these costs but also in interpreting their implications for strategic management. Manufacturing overhead includes all other production costs that cannot be directly attributed to labor or materials. It covers expenses such as factory rent, utilities, equipment maintenance, and indirect labor (e.g., supervisors, quality control personnel).

Google keyword position checker

Combining a product’s component costs with conversion expenses results in a lower threshold value. This allows the manufacturer to recoup some of the expenses spent in producing the items. Prime conversion costs costs and conversion costs are two methods that businesses use to measure the efficiency of their production operations.

- Both these costs can be used by the management to evaluate the efficiency of the production process in different ways.

- Storage costs are generally excluded from the cost of inventories, except when necessary for the production process before a further production stage.

- Conversion Cost includes direct labor and manufacturing overhead, covering all production expenses.

- Van conversion costs might seem daunting initially, but remember—you’re not just buying a vehicle modification.

- The other difference is that the cost of direct materials is only included in prime costs.

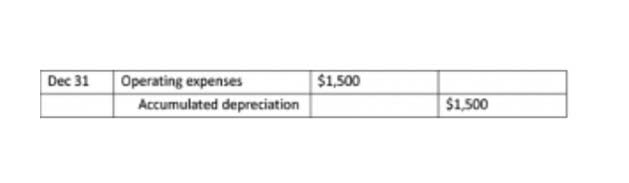

Consider a professional furniture maker who is hired to make a coffee table for a customer. The prime costs for creating the table include the cost of the furniture maker’s labor and the raw materials required to construct the table, including the lumber, hardware, and paint. Prime costs plus conversion costs does not equal manufacturing cost. Some costs, notably labor, are included in each, so adding them together would overstate manufacturing cost. Examples of manufacturing overhead include the utilities, indirect labor, repairs and maintenance, depreciation, etc. that is occurring within a company’s manufacturing facilities. The term conversion costs often appears in the calculation of the cost of an equivalent unit in a process costing system.

- International PPC Agency Navigating the complexities of international markets can be daunting for businesses seeking to expand their reach.

- To optimize your website for conversions, you need to know who your target audience is, what they are looking for, and how they interact with your website.

- You can also use tools such as surveys, feedback forms, and user testing to gather qualitative insights from your audience, such as their opinions, motivations, and objections.

- The calculation of the cost of sales, which is reported on the income statement, also depends on the conversion cost.

- These expenditures might include expenditure related to, but not limited to, raw materials, labor, supplies, equipment, etc.

- YouTube Growth Agency YouTube has transformed how brands connect with audiences.

Understanding the differences and similarities between them can help managers and investors make better decisions about the performance and profitability of a manufacturing business. In this section, we will explore the definitions, components, and calculations of the cost of conversion and the cost of goods sold, as well as some of the advantages and disadvantages of using each method. It’s important to note that the cost of conversion calculation may vary based on the specific requirements and accounting practices of each business. By accurately calculating the cost of conversion, manufacturers can gain insights into their production expenses, identify areas for cost optimization, and make informed pricing decisions. Many customers finance van conversions through personal loans, RV loans, or by increasing their van purchase loan to cover conversion costs. As a Colorado van conversion company that’s been building adventure-ready vans for nearly a decade, The Vansmith has converted hundreds of vans across every budget range imaginable.

Digital Marketing Strategies for Manufacturers

By analyzing the various components of conversion costs, businesses can make informed decisions to optimize their production processes and enhance profitability. In summary, conversion cost bridges the gap between raw materials and finished products. It represents the labor and overhead expenses necessary for production. By understanding and managing conversion costs effectively, businesses can enhance their competitiveness and profitability.